Antimicrobial plastic is a new type of material with antibacterial and bactericidal properties, which can keep the material clean and reduce cross-infection caused by using plastic products. In some developed countries in Europe and America, people have already used antibacterial plastics more or less on telephone handsets, computer keyboards, and handrails of buses. At present, antibacterial plastics have begun to be used in large-scale home appliances, communication equipment, and automobile manufacturing. .

Plastics can be antibacterial because of the addition of antibacterial agents during their production. With this method, the amount of the antibacterial agent is large and the cost is increased. In order to reduce the cost, the antibacterial agent with extremely fine particles can be made into a spray liquid and sprayed on the surface of the plastic mold. During the molding process, the antibacterial agent penetrates into the surface of the plastic product, and after appropriate heat treatment, the antibacterial agent is combined with the plastic product.

Antibacterial agents for plastics are divided into organic, inorganic and natural three major categories. Organic antibacterial agents are mainly composed of organic acids, phenols, and alcohols. They have strong bactericidal power and good efficacy. However, they produce irritating odors during processing, they are easy to migrate in plastics and have poor heat resistance. Natural and polymeric antibacterial agents have not been used in large-scale applications in plastics due to poor heat resistance and processing difficulties. The use of these antibacterial agents in combination with inorganic antibacterial agents can combine the advantages of both, with both the immediateness and sustainability of organics and the safety and durability of inorganic antibacterial agents. Inorganic antibacterial agents are metal, metal ions such as silver, copper, zinc, etc., which have antibacterial ability, and are supported on an inorganic carrier, and the carrier is used for sustained release to achieve antibacterial activity. Its carrier is mainly zeolite, titanium dioxide, zirconium phosphate, silica gel and so on. Since the silver ion has a small toxicity, strong antibacterial ability, and it is difficult to accumulate in the human body, it is currently commercialized and the silver-based antibacterial agent has become the most widely used antibacterial agent.

From the prospect of development, the use of nano-technology modified inorganic antibacterial agent is the most popular. Due to the ultra-fine particle size, these antibacterial agents increase the contact area with bacteria, and can penetrate the bacterial cell wall into the cell body, destroy the activity of cell synthesis enzymes, and make cells lose their ability to divide and proliferate and die. Therefore, the functional nano inorganic antibacterial agent has extremely excellent antibacterial efficiency, and is safe, non-toxic, long-lasting, and has a sustained release effect, and has the light stability and thermal stability unmatched by ordinary silver antibacterial agents. In recent years, there have been advances in the use of nano-semiconductor particles for photo-catalytic sterilization. The most important feature of this antibacterial agent is that it not only kills bacteria, but also completely degrades organic substances, thus avoiding "white pollution."

The development and application of antibacterial plastics in our country is constantly evolving. The National Engineering Research Center of Engineering Plastics has obtained antibacterial, non-discoloring and low-cost composite inorganic antibacterial agents through ion exchange and multi-layer coating technology, and manufactures antibacterial plastics and their products through the unique antibacterial masterbatch technology. Strengthen the exertion of antibacterial power. After years of research, the center and the Haier Group, the first to launch domestic antibacterial home appliances products. Xiaoya Electric Group also applies nano-antibacterial materials to washing machines and other fields. However, as a whole, the development and application of antibacterial plastics in China needs to be strengthened. There are many manufacturers of toys in our country. In addition to domestic sales, the export volume is very large. According to statistics, the amount of plastic raw materials required by the domestic toy industry is approximately 1.5 million tons per year. This industry can use a lot of imported raw materials, domestic raw materials used very little, the reason is that foreign toys are strict health and safety standards, including the use of toys will not cause bacterial infection, and China's antibacterial plastics for the toy industry can not meet Requirements, so that manufacturers have to seek raw materials abroad. Actively develop anti-bacterial plastics, and relevant units should make efforts.

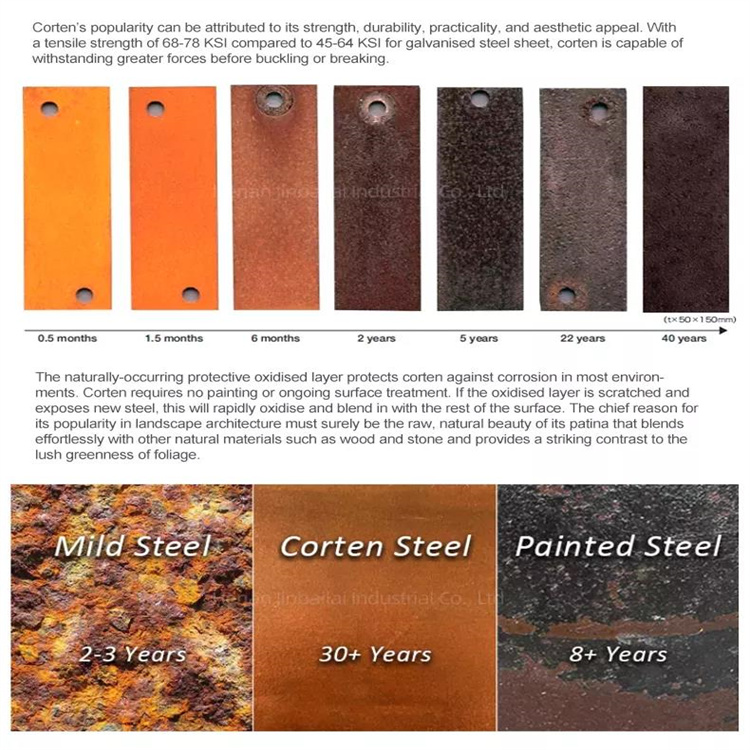

Weathering steel molding sculpture, landscape, carving, weathering steel rust plate sculpture and landscape walls are common forms. Because of its simplicity and efficiency, many landscape projects are made of this material. The use of weathering steel rust plate sculpture is not only beautiful in appearance, but also practical, and the maintenance cost is relatively low. The color, brightness and saturation of weathering steel rust plate sculpture are higher than those of general materials, and it is easier to highlight in the background of garden plants. Weathering steel rust board sculpture is relatively simple, easy to be shaped into a variety of shapes, and can maintain excellent integrity. The surface of weathering steel rust board sculpture is a layer of rusty red material, which feels very rough and has a very special texture. This special fine oxide layer formed on the surface of weathering steel has a stable and even natural rust red color, making it an attractive material for building exterior walls. Weathering steel rust plate sculpture is widely used in phenomenon decoration. It is a new type of steel that integrates new technology, new data and new strangeness. It is one of the leading steel varieties. Heat treatment of weatherproof steel plate sculpture includes preparation heat treatment, final heat treatment and surface lifting. General heat treatment defects refer to various defects of weathering steel plate sculptures in the final heat treatment process or later production process and use process, such as quenching cracks, deformation deviations, unqualified hardness, laser cutting cracking of metal materials, drilling cracks, early damage of weathering steel plate sculptures, etc. The following are detailed instructions on cracking and hardness.

|

Product Name

|

Outdoor Modern metal craft corten steel garden leaf sculpture

|

|

Material

|

corten steel,mild steel,etc.

|

|

Color

|

Powder coated or Rusted red

|

|

Size

|

160cm or custom

|

|

Used

|

home decoration

|

Why is corten steel so popular?

Packing&Shipping

About mobile steel storage tool cabinet packaging and shipping

We handle in a careful and economic way for ocean shipping, like paper box,pallet,or carton. Package size and

container loading quantity are calculated by engineers based on products size in order to work out a best solution.

Every piece is fixed by protective foam,plastic tape,batten etc. to protect products from shipping damage.

Corten Steel Sculpture,Corten Sculpture,Corten Steel Artwork

Henan Jinbailai Industrial Co.,Ltd , https://www.jblbbqgrill.com